Pattern Recognition is the new front and center skill for industrial knowledge workers.

A diversified industrial factory builds snowflakes. Each product may be the only one of its kind, although similar to thousands of others. This natural variation in product design is driven by the ratio of product cost to operating cost. For example, if the product consumes a great deal of energy to perform its work, then the customer will ask for a product that is tuned to deliver the maximum efficiency for a particular application.

As of this writing I’ve worked closely with eleven diversified industrial factories. In every case, one of the first things the staff told me was how different or special they are; that many of the common rules don’t apply to them. The staff is correct from the standpoint that most factories produce common (repetitive) components or products, and can use a simpler operating system to effectively manage the business. The staff has probably already experienced a consultant or two who tried to apply common principles to a peculiar environment. They do not want to clean up a big mess after I leave.

So why is pattern recognition a big deal? Because even in dizzyingly complex environments, there is structure, there are patterns, but they are often difficult to find, or difficult to formulate. This creates opportunity to gain competitive advantage.

At the moment, seemingly all the new wealth is being created at the nexus of high technology and high performance culture. A big part of high performance culture is the intrinsic desire we all have to make our days more productive. We recognize patterns of repetition, and want to eliminate them. Today this is easier than ever – just turn them into code.

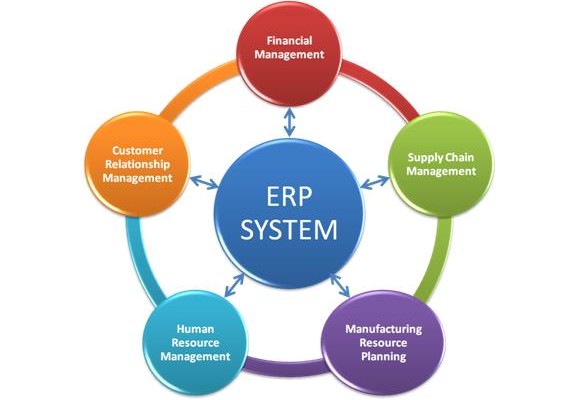

For example, one company may employ inventory analysts to develop a “plan for every part” – ie: to manage Item Planning parameters like Lead Time, Minimum Order Quantity, and Forecast Bills of Material. A smarter company will realize that much of this analysis is repetitive, and will formulate a set of equations that provide a remarkably accurate result, allowing the analysis to be performed frequently at little cost, and redeploying the analysts to solve more peculiar and interesting problems.

Another example is the shop order release process. One company may employ production control analysts to determine on a case by case basis which jobs should be released to the factory next. A more progressive company will ‘walk the process’ and codify the rules, so the computerized system can determine what is OK to release. Then, the shop floor operations personnel can release their own work as a natural extension of reporting work completed.

Another type of pattern recognition is the ability to recognize dependency. Often tasks completed in the office are not well defined, or routed, compared to the shop floor. Considerable effort must be deployed to define the work sequences, recognize the waste, and streamline them, while maintaining multiple parallel paths to accommodate separation of skillsets and duties. Conversely, there are patterns of structure, almost like DNA, that define the nature and behavior of task deliverables, that do not fit inside the data model of an ERP. It is important to find these patterns of structure and flow, because they can be used to autonomate project planning, scheduling and management.